In-house process

development & tech support

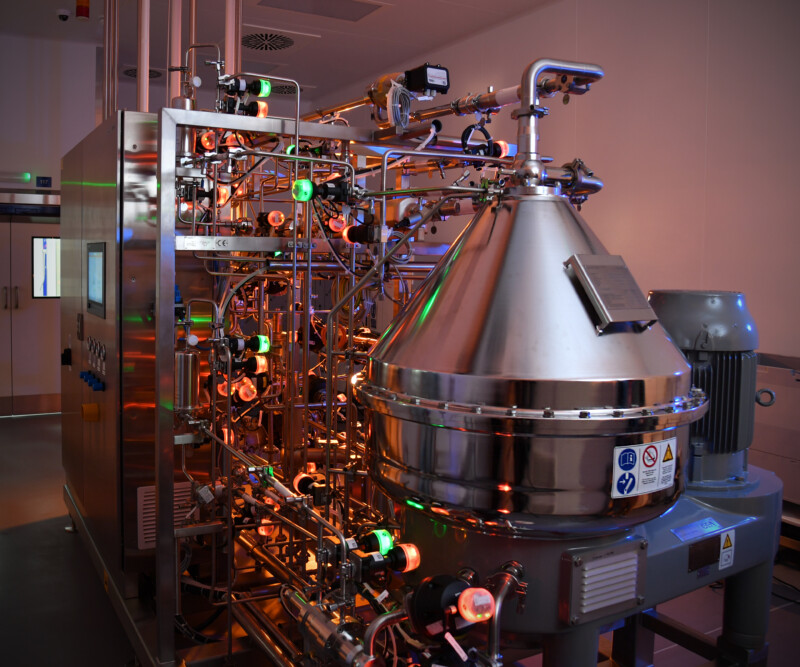

Process Development & Scale Up

We are focussed on developing robust and efficient fermentation and purification processes to maximise product quality and yield.

We accomplish this through use of research study designs and scale-down models to optimise process conditions that can be translated through scale-up strategies to cGMP manufacturing. Our expertise in up-stream and down-stream process development is complemented by comprehensive analytical support, a range of process scale options and state-of-the-art technologies.

Formulation and

product characterisation

Compiling a robust data package that defines the characteristics of a biotherapeutic agent for regulatory and process design purposes is essential. We develop methods in parallel with up-stream and down-stream activities to evaluate product quality and purity. Our experience, agility and adaptability allow us to develop timely solutions to complex problems.

This learning not only influences the manufacturing process but allows scientific sound formulation strategies to be developed. Our experience in liquid and lyophilised dosage forms for injectable delivery systems ensures a high-quality stable product, that is safe and efficacious is delivered.

Technology transfer

into manufacturing

We form integrated teams to facilitate translational activities between Development and Pharmaceutical cGMP areas. Our flexible work ethic promotes engagement of Production and Quality Control staff during late stage Development activities, followed by a man-in-plant strategy during transfer to Production or Quality Control areas. The combination of skills and experience across the organisation is complemented by use of paper based systems which ensure that process controls, build up through extensive Development records, are translated to Production and QC Batch Manufacturing Records and SOPs.

- © 2024 Porton Biopharma

- Website by blue bee

- Terms of Use

- Privacy Policy

- Cookie Policy

Registered in England and Wales, company number 9331560. Registered office at Manor Farm Road, Porton Down, Salisbury, Wiltshire SP4 0JG. VAT number is GB 206 6518 18.